Prevents moisture, carbon, and sludge contamination in OLTC oil.

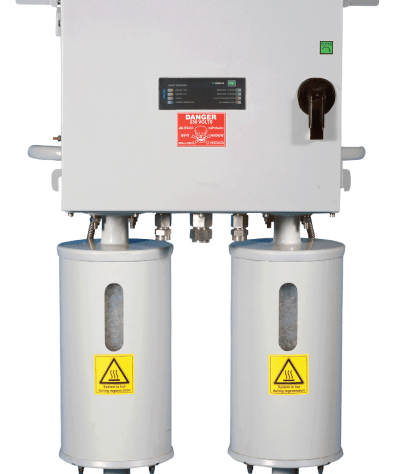

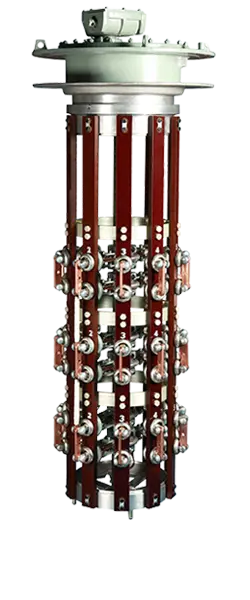

On-line Oil Filtration Unit

Why Oil Filtration Matters

- OVERALL BENEFITS

- Conventional vs EMR Solution

- Key Features

- Support & After-Sales

OVERALL BENEFITS

Maintains oil quality and dielectric strength.

Extends life of OLTC & transformer.

Reduces maintenance downtime and costs.

Provides uninterrupted filtration while transformer is in service.

Eliminates frequent oil replacement.

Conventional vs EMR Solution

Conventional Oil Maintenance

Manual oil replacement.

High cost and downtime.

Environmental disposal issues.

On-line Oil Filtration Unit

Continuous filtration during operation.

Cost-effective, safe, and eco-friendly.

Zero downtime for filtration.

Comparison Table

Parameter | Conventional Oil Change | On-line Oil Filtration Unit |

Oil Quality | Restored temporarily | Maintained continuously |

Transformer Downtime | Required | Not required |

Operating Cost | High (oil + labour) | Low |

Environmental Impact | Disposal problems | Eco-friendly |

OLTC Life | Reduced | Extended |

Key Features

On-line filtration without stopping transformer.

Removes carbon, moisture, and sludge.

Compact skid-mounted design.

User-friendly controls.

Designed for different OLTC models.

Long service life with minimal maintenance.

Support & After-Sales

Spares and replacement filters available.

Retrofit solutions for existing OLTCs.

Training programs for operators.

Dedicated technical support.

We provide a wide range of spares and accessories for your mission critical equipments. We are committed to provide best customer services to ensure smooth operations at all times

Our Clients